Silver Brazing Alloys

Brazing is a metal joining process whereby two or more metal objects are joined by melting and flowing a filler metal (brazing alloy) into the join. The brazing alloy must be of a lower melting point than the two metals being joined.

Cadmium Free Alloys

Cadmium free alloys have been developed to be used where the presence of cadmium is unacceptable. For example, the food and beverage industries and laboratory and medical equipment. These alloys are suitable for use on most ferrous and non ferrous metals but due to the capillary flow being less than the cadmium bearing alloys - quite often a higher silver content is required to assist the capillary flow.

Product Code | Tip Colour | Ag % | Melting Temp ºC | Approx Tensile Strength | Available Forms | Indicated Applications |

|---|---|---|---|---|---|---|

SB34CF | Emerald Green | 34 | 630 - 730 | 27 | Rods, Rings, Wire & Shim | Steel and copper alloys and improved ductility. |

SB39CF | Dark Brown | 39 | 650 - 705 | 28 | Rods, Rings, Wire & Shim | Steel and copper alloys and improved ductility. |

SB402CF with 2% Nickel | Gold | 40 +Ni | 660 - 780 | 36 | Rod, Wire & Shim | Stainless, carbide steel & other nickel alloys |

S45CF | Rockmelon | 45 | 640 - 680 | 32 | Rod, Rings & Shim | Specialised alloy for stainless & carbide steels |

SB49CF LM | Citronella | 49 | 670 - 690 |

| Rod & Shim | Agricultural applications, carbide saw tips and various mining applications. |

SB49CF HM | Citronella | 49 | 680 - 705 |

| Rod & Shim | Agricultural applications, carbide saw tips and various mining applications. |

SB56CF | White | 56 | 618 - 650 | 36 | Rod, Rings Wire & Shim | Copper, steel & stainless steel alloys. |

Cadmium Bearing Alloys

Cadmium bearing alloys offer an excellent combination of melting range, capillary flow and mechanical properties. These cadmium bearing alloys would be recommended for use as the most economical alloys where the presence of cadmium is acceptable. They should only be used in well ventilated areas and in accordance with information supplied with the product.

Product Code | Tip Colour | Ag % | Melting Temp ºC | Approx Tensile Strength | Available Forms | Indicated Applications |

|---|---|---|---|---|---|---|

SB34LT | Salmon Pink | 34 | 610 - 670 | 28 | Rods, Rings, Wire & Shim | Steel and copper alloys and fluid properties. |

SB45 | Oriental Blue | 45 | 607 - 620 | 30 | Rods, Rings, Wire & Shim | Superior ductility, melting range & strength. |

SB50 | Palm Green | 50 | 620 - 640 | 30 | Rod | Superior ductility, melting range & strength. |

SNI50 with 3% Nickel | Mid Grey | 50 +Ni | 645 - 685 | 46 | Rod & Shim | Specialised alloy for stainless & carbide steels |

Phosphoros Alloys

These alloys are recommended for fluxless brazing of copper and are used extensively in the plumbing, air conditioning and refrigeration industries. As the silver content increases, so does the resistance to vibration, temperature change and stress. These alloys can also be used on brass and bronze with the application of soldering flux.

Product Code | Tip Colour | Ag % | Melting Temp ºC | Approx Tensile Strength | Available Forms | Indicated Applications |

|---|---|---|---|---|---|---|

SPHOS 2 | Yellow | 2 | 645 - 704 | 35 | Rod | Plumbing |

SPHOS 5 | Silver | 5 | 646 - 740 | 40 | Rod | Air conditioning & refrigeration. |

SPHOS 15 | Brown | 15 | 645 - 700 | 45 | Rod & Shim | Refrigeration & high stress. |

Flux Coated

Product Code | Tip Colour | Ag % | Melting Temp ºC | Approx Tensile Strength | Available Forms | Indicated Applications |

|---|---|---|---|---|---|---|

SB45CF | Blue | 45 | 640 - 680 | 32 | Rod | Specialised allow for stainless & carbide steels |

SB56CF | Orange | 56 | 618 - 650 | 36 | Rod | Copper, steel & stainless steel alloys. |

Brazing Material Cross Reference Chart

Parent Material | Cadmium Group | Phosphorus Group | Cad Free Group | Silversmith Solders | 72% | 56% | SNI50 | SB402CF | |

|---|---|---|---|---|---|---|---|---|---|

Copper | R | R | R | P | R | R | P | P | |

Copper Base Alloys | R | R | R | P | R | R | P | P | |

Mild, Carbon, Low Alloy Steels | R | N | R | P | R | R | R | R | |

Stainless & Heat Resistant Steels | R | N | R | P | R | R | R | R | |

Cemented Carbides | P | N | P | P | P | P | R | R | |

Nickel Based Alloys | P | N | P | P | P | P | R | R | |

Aluminium | N | N | N | N | N | N | N | N | |

Silver and Silver Alloys | P | N | P | R | P | P | N | N | |

P = Possible but not generally used | N = Not recommended | R = Recommended | |||||||

Pre-form Profiles

Silver brazing alloy rings and washers are available in the complete SBA range which can be manufactured to our clients specifications. SBA is equipped to provide brazing alloys in the optimum form so our clients are able to obtain maximum efiiciency and performance in application.

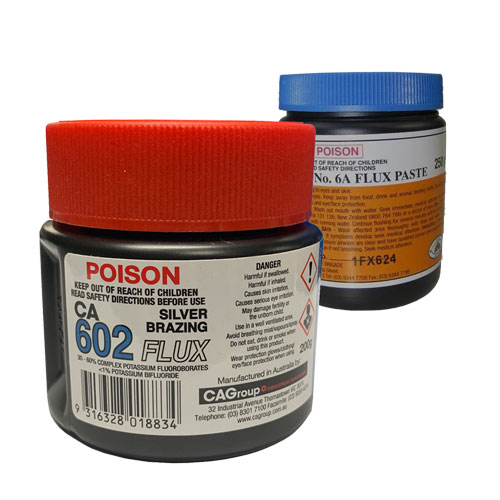

Brazing Flux

SBA offers a range of brazing fluxes, manufactured to the hightest quality standards that are sutiable to use with all our brazing products.

Available in:

602 Brazing Flux

200g jar and 1kg tub

603 Brazing Flux

220g jar, 5kg Tub and 13 kg Tub.

Tenacity 6

250g Jar